Tape 101 – Materials, Constructions, and Applications

Adhesive tapes are engineered material systems designed to solve complex challenges in bonding, protection, insulation, and process efficiency. Each layer, from the carrier to the adhesive chemistry, affects mechanical performance, environmental resistance, and manufacturability.

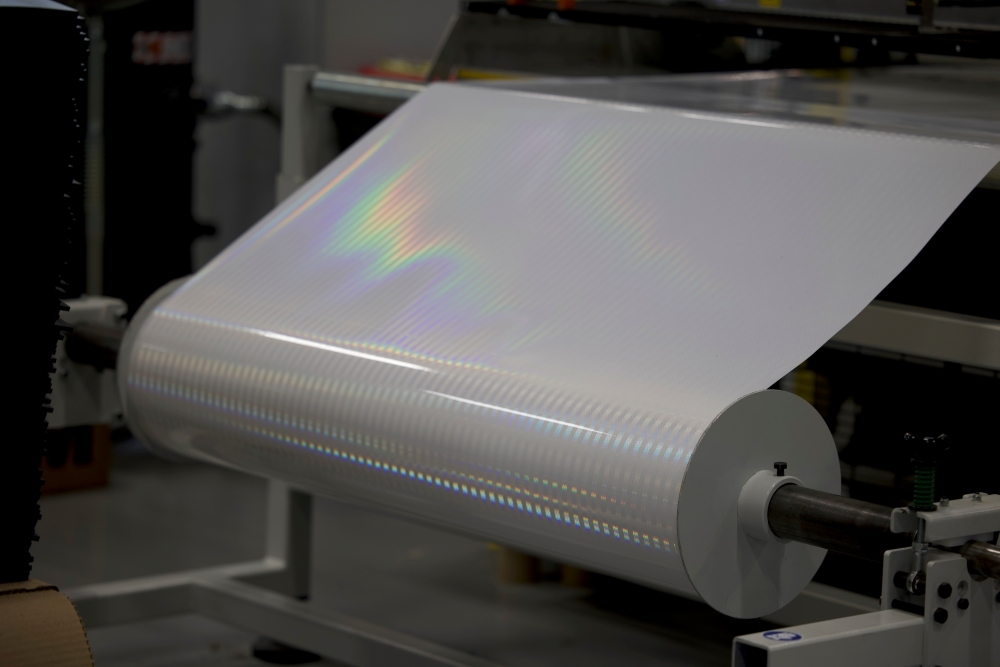

At TapeCase, we apply advanced converting concepts, including slitting, laminating, die-cutting, and cleanroom processing, to help engineers translate these materials into custom solutions for highly specialized applications.

The Anatomy of Adhesive Tapes

Most adhesive tapes share a common structure, with each component contributing to overall performance:

- Backing / Carrier: The primary flat, flexible material that provides overall structure, strength, flexibility, and environmental resistance

- Adhesive Chemical: The tacky, or sticky, tape layer that adheres the carrier to the desired surfaces through pressure-sensitive adhesive compounds

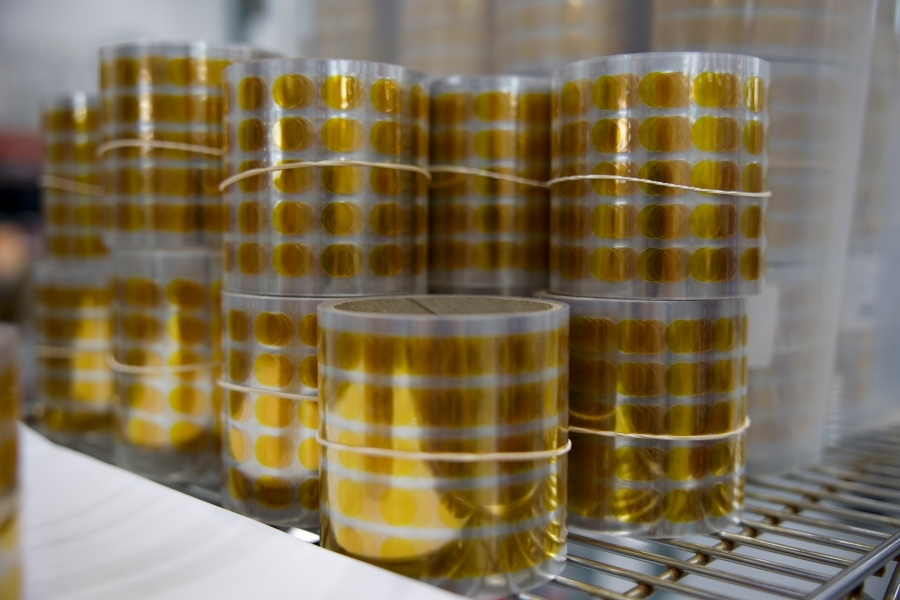

- Liner: Protects the adhesive during storage and converting, enabling clean application

- Core: The interior structure that the tape is wound onto for clean, efficient dispensing of tape during application; can be customized with a brand log

Carrier Materials and Properties

The carrier defines much of a tape’s behavior under mechanical stress, heat, or environmental exposure. Engineers select carriers to match application requirements such as flexibility, dielectric strength, or thermal resistance.

Common tape carrier materials include:

- Papers and fabrics

- Foams and pads

- Metal foils

- Films such as PET, polyimide, UHMW, PTFE, or vinyl

- Gritted anti-slip material

Adhesive Chemistries and Performance

The adhesive defines many functions of a tape. TapeCase primarily works with pressure-sensitive adhesives (PSAs), chosen for their ability to bond with light pressure and remain tacky over time.

Common tape adhesives include:

- Acrylic: Bonds to various surfaces with high strength and long-term durability; can offer UV stability

- Rubber: Cost-effective, high initial tack, and reliable for short-term use

- Silicone: Bonds well to low surface energy substrates, such as other silicones, and withstands extreme temperatures

Double-Sided Tape and Advanced Design Options

By coating adhesive on both sides of a carrier, double-sided tapes provide slim, strong bonds. They improve aesthetics, reduce weight, and simplify assembly in industries such as automotive, signage, medical, and electronics.

EXAMPLE: 3M™ Double Coated Tape GPT-020

A flexible, strong polyester carrier coated on each side with a modified acrylic adhesive for high and low surface energy substrates. Handles high temperatures, indoor applications, and outdoor environments. Ideal for assembling furniture, signage, and more.

Transfer Tapes for Ultra-Thin Bonding

Adhesive transfer tapes skip the carrier altogether, offering versatility in layering and bonding. These tapes are essentially a sheet of adhesive sandwiched between two disposable liners.

Transfer tapes are especially useful for laminations, extremely slim designs, and for use with adhesive tape guns. Their versatility makes them valuable in electronics, aerospace, and other high-performance environments.

Engineering Custom Solutions with TapeCase

From prototype to production, TapeCase converts thousands of flat, flexible materials with precision services for die-cutting, slitting, rewinding, lamination, and cleanroom processing. Our engineers work with you from material selection through full production to deliver tape solutions tailored to your exact application.