Our Material & Fabrication Expertise

- Die-free CAD based cutting

- Clean, intricate shapes

- Multi-layer laminations

- Adhesive-backed parts

- Conductive foams & pads

- Foils, papers & films

Industries TapeCase Helps with Prototypes

- Electronic Manufacturing

- Aerospace

- Aviation

- Medical Device & Wearables

- Plastic Injection Molding

- General Manufacturing & Assembly

How We Prototype Your Custom Parts

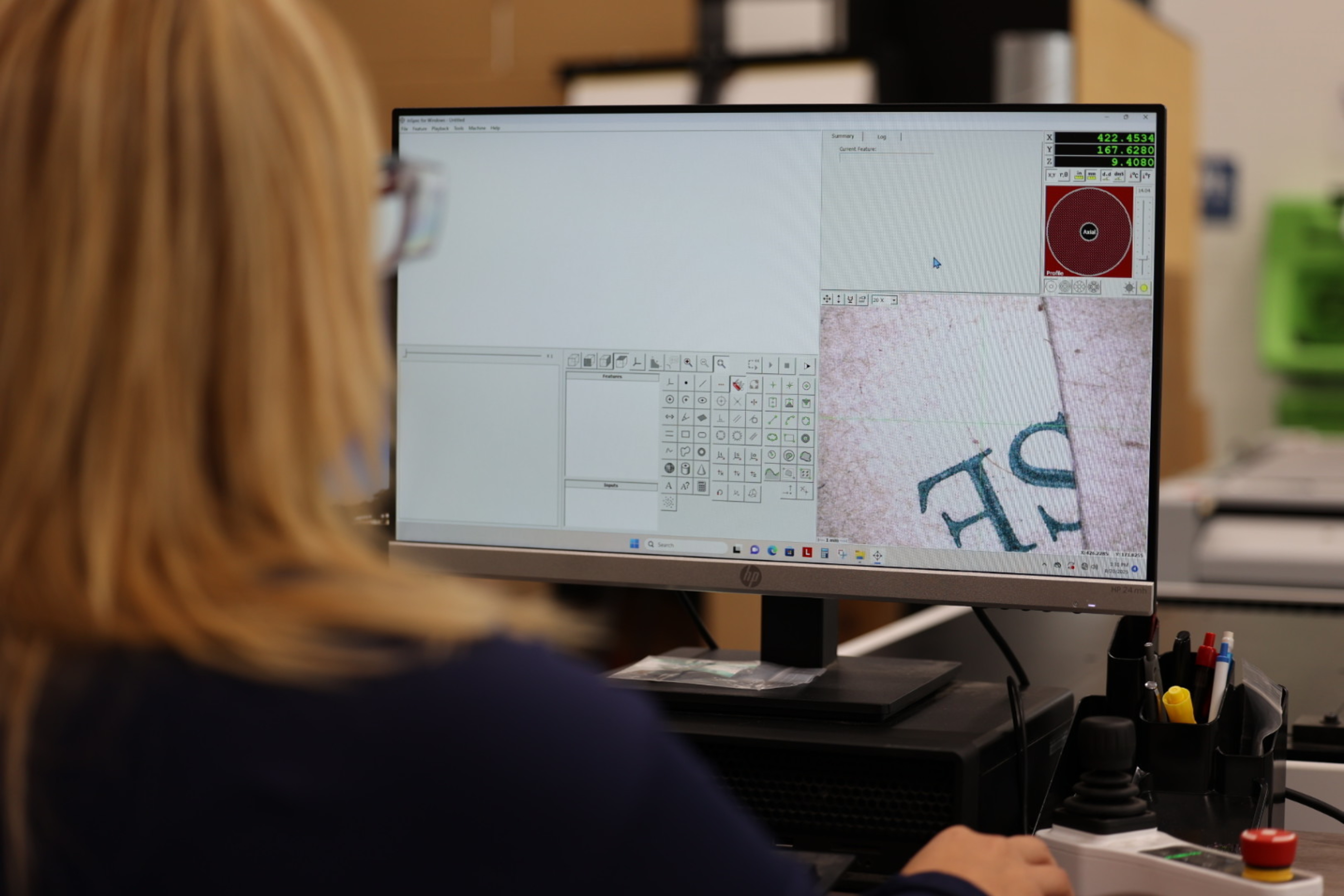

We specialize in dieless prototyping using laser cutting, plotters, CAD workflows, and precision lamination to produce clean, accurate parts at tight tolerances. By avoiding the need for a metal die upfront, you can skip specialized tooling costs and delays as you design and iterate.

Our prototyping capabilities include:- Laser cutting

- Kiss cutting & plotter equipment

- Slitting & rewinding

- Multi-layer laminations

Our extensive in-house material library means you can sample, test, and iterate without waiting on long lead times or committing to bulk purchases.

Flexible Solutions for Complex Builds

Our experts help you move from prototype to production with a fast, flexible iteration process and hands-on support. We collaborate closely with your engineers and designers to refine each version, troubleshoot early, and prepare for scaled-up production runs.

Why prototyping teams choose TapeCase:- Rapid prototyping without upfront custom tooling

- Hundreds of materials in stock for sampling

- End-to-end design and engineering input

- Support for evolving product lines

- Easy CAD file integration

Get expert advice about prototyping with our precision converting services

Our team of experts is ready to chat and help whether you need advice finding the right material or are looking for custom converting capabilities. Get in touch today and move your project to the next step.