Tapes We Commonly Perforate

- Carton sealing tapes

- Masking tapes

- Stick-to-skin tapes

- Foils & films

- Paper & kraft tapes

- Protective films

Industries Using Perforated Tapes

- MRO & Facility Maintenance

- Packaging

- Medical Device & Wearables

- General Manufacturing & Assembly

How Do You Perforate Tape?

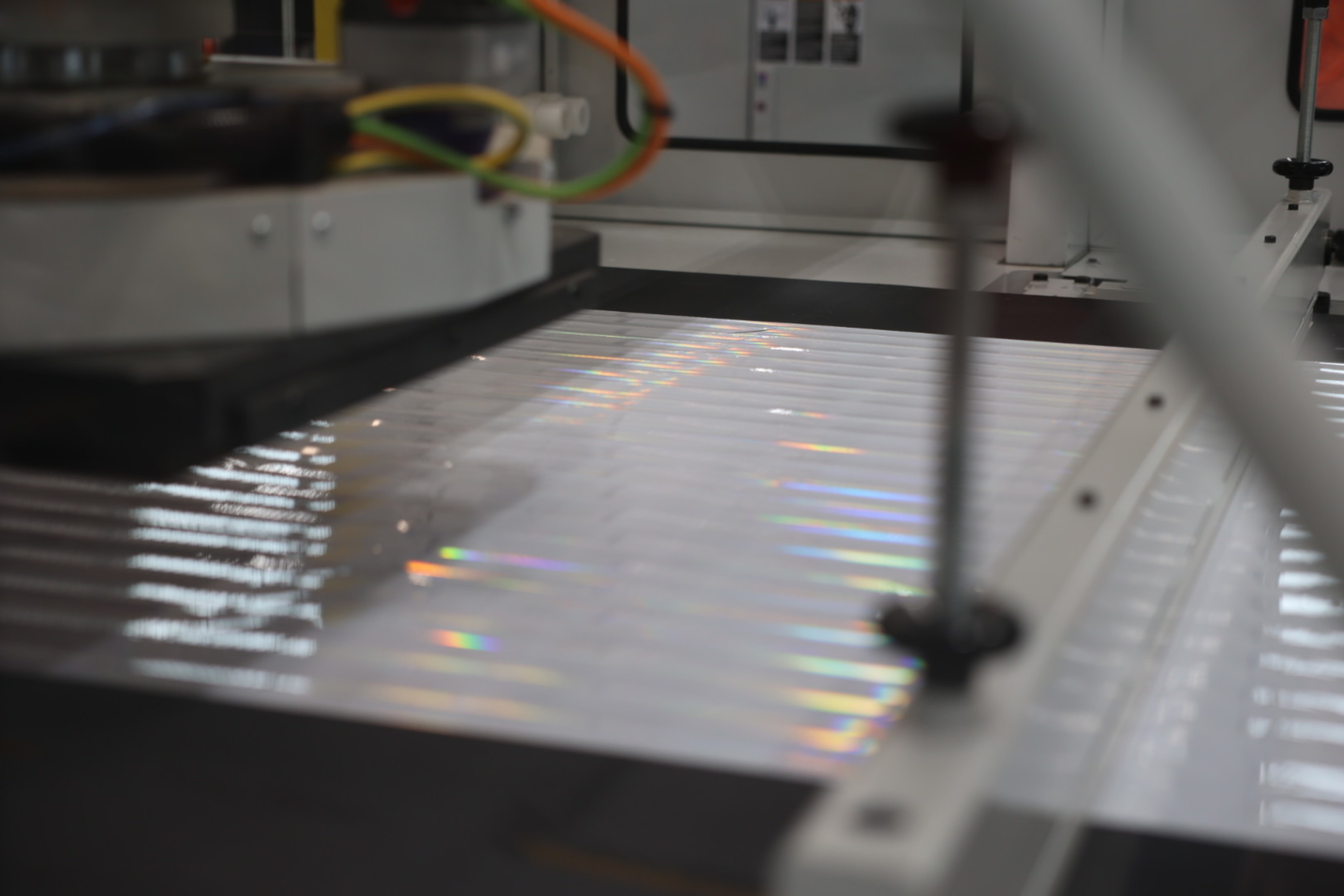

Our perforating equipment uses serrated blades to create tight, controlled tear lines with a sequence of small holes or slits across the tape. Customization options include micro-perforations and a range of other perforation types whether you’re creating 6” segments for sealing boxes or 12” strips for field kits.

Our perforation machines allow for:- Custom perforation lengths and spacing

- Clean tear-lines without fraying

- A wide variety of tape inputs

- Micro-perforations

How Does Perforated Tape Help?

Perforated tapes are easier to use and can eliminate the need for cutting tools, simplifying workflows and speeding up repetitive tasks. It helps ensure uniform tape usage across teams and improves consistency without the need for measuring.

How perforated tapes improve your process:- Speed up repetitive tasks

- Improve safety by removing blades

- Reduce over-usage and waste

- Make tape easier to manage and distribute

- Eliminate the need for measuring tools

Get expert advice on custom tape perforations

Our team of experts is ready to chat and help whether you need advice finding the right material or are looking for custom converting capabilities. Get in touch today and move your project to the next step.