Common Gasket Materials

- Silicones, foams & rubbers

- Vibration dampening gaskets

- High-temp & high-strength gaskets

- Multi-functional material laminations

- Conductive foils & pads

Industries Using Converted Gaskets

- Plastic Injection Molding

- Medical Device & Wearables

- Electronic Manufacturing

- MRO & Facility Maintenance

- Automotive & Transportation

- General Manufacturing & Assembly

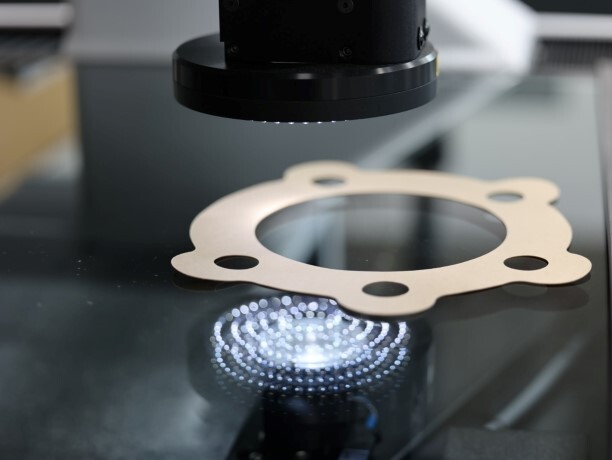

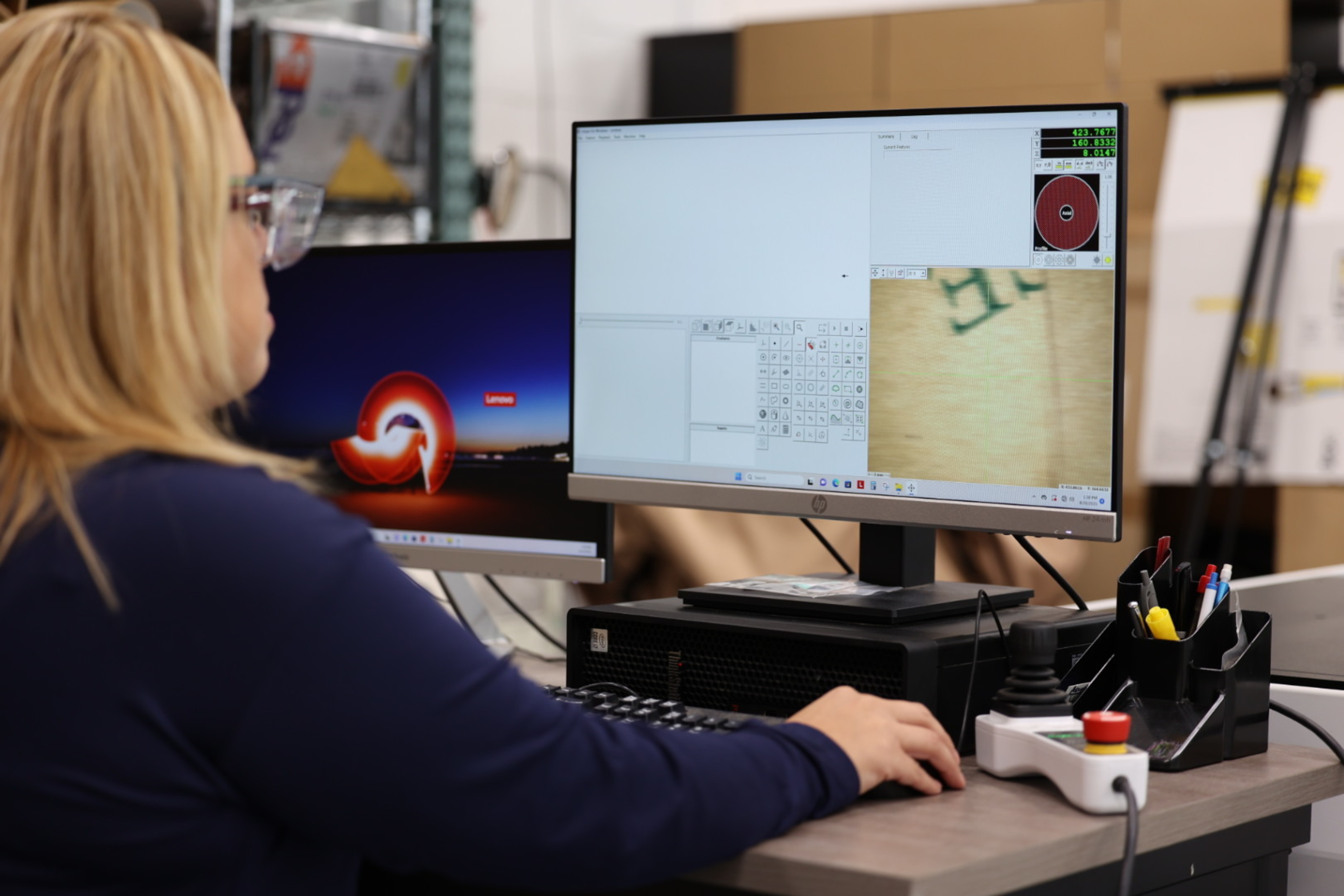

How We Create Custom Gaskets

Our experts use precision converting processes and top-tier materials to cut gaskets for your designs. With our endless options for shapes, thickness, sizes, lamination, and adhesives, you can design a cost-effective and scalable gasket for nearly any task.

Our equipment supporting custom gasketing:- Die-cutting for custom shapes and sizes

- Lamination for multi-layer stacks

- Custom liners, sheets, and field-ready kits

- Design file integration and rapid prototyping

Why Choose a Converted Gasket?

Whether you’re reverse engineering legacy parts or trying to reduce defects to scale production, our converted gaskets offer a consistent solution to reduce the need for special equipment, streamline labor input, and achieve reliable performance.

TapeCase converting services support:- Hands-on material selection and iteration support

- Low-to-high-volume production

- Fast turnarounds to reduce downtime

- Flexible minimum order quantities

Get expert advice about creating custom converted gaskets

Our team of experts is ready to chat and help whether you need advice finding the right material or are looking for custom converting capabilities. Get in touch today and move your project to the next step.