Plastic Injection Molding

Working with molded plastic parts is easier with tapes custom converted to attach components, protect surfaces, and gasket seams. Our converting expertise helps you improve part quality, reduce cycle times, and streamline adjacent production processes.

Tape Applications

in Plastic Injection Molding

Converting Services for Plastic Injection Molding

Tape Slitting

Convert adhesive-backed tapes and films into custom-width rolls for bonding, masking, or protecting molded parts.

- Match roll widths to your application tools, molded part dimensions, and worker preferences

- Reduce waste and manual trimming with custom-width tape rolls

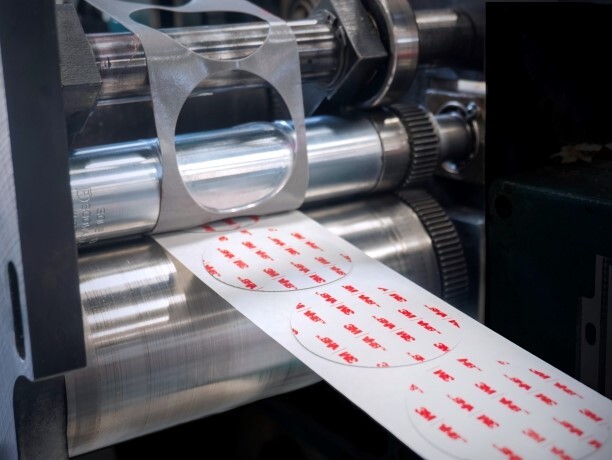

Die-Cutting

Cut clean, scalable shapes from tapes, foams, films, and more for attaching, gasketing, and protecting complex molded plastic parts.

- Create small, precise tape parts with exact tolerances to fit seamlessly with your molded part geometry

- Reduce defects and rework with more consistent prefabricated application formats

Sheeting

Obtain converted adhesive-backed materials for on-site custom plotter cutting or prefabricated strips for specific plastic molded parts and tasks.

- Simplify sourcing and handling with uniform sheeted tape strips and sheets

- Make placement easier and more consistent to reduce waste

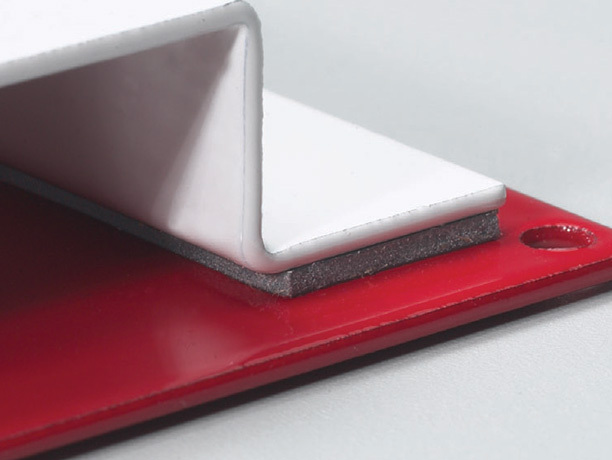

Custom Part Fabrication

Customize multi-layer, die-cut parts with adhesive backings for bonding, gasketing, and beyond in complex plastic assemblies.

- Combine flat, flexible materials into precision stack-ups with multiple functions

- Customize liners, adhesives, materials, shapes, and more

Talk to a Converting Expert

Our team of experts is ready to chat and help whether you need advice finding the right material or are looking for custom converting capabilities. Get in touch today and move your project to the next step.