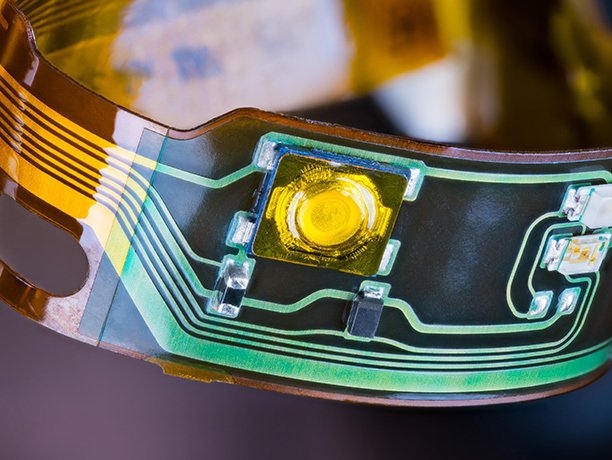

Medical Devices & Wearables

Create smarter custom stick-to-skin wearables with our inventory of high-quality medical tapes and precision converting equipment. Our specialized services and support for cleanroom converting help you create reliable, comfortable, and scalable solutions for detecting vitals, managing disease, and tracking health.

Applications

in Medical Devices & Wearables

Converting Services for Medical Device Builds

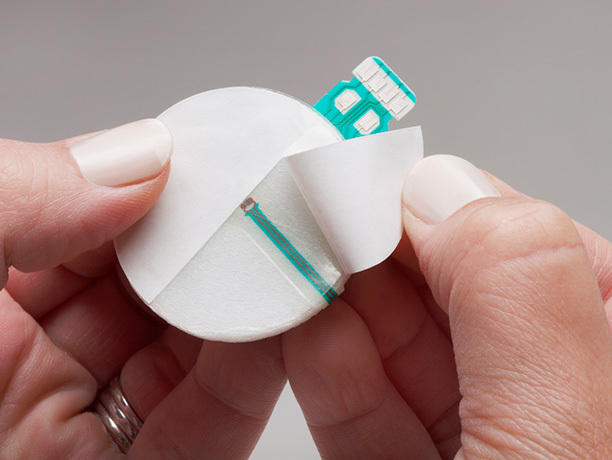

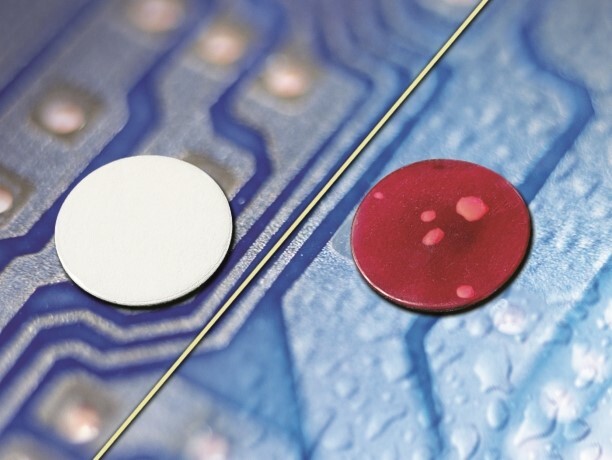

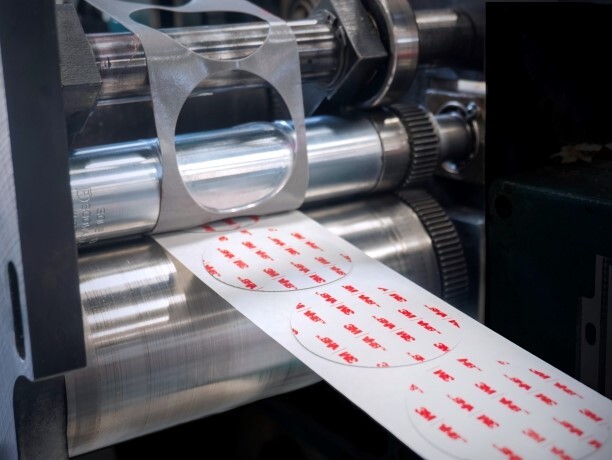

Die-Cutting

Cut out complex, clean shapes from foams, films, and tapes for use in wearable sensors, stick-to-skin patches, and housings.

- Create precision medical parts using high-volume or medium-volume die-cutting equipment

- Enable clean, comfortable skin contact with custom-shaped films, fabrics, and medical adhesives

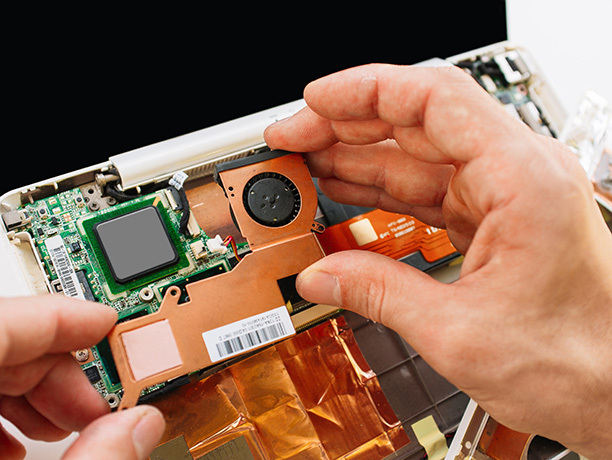

Multiple Lamination

Combine adhesives, carriers, liners, conductive pads, insulating films, and more into multi-functional stacks for compact wearables requiring comfort and performance.

- Build flexible constructions balancing adhesion, skin safety, and ease-of-use across multi-day wearable devices

- Enable complex designs by integrating up to seven layers for sealing, thermal management, bonding, and more

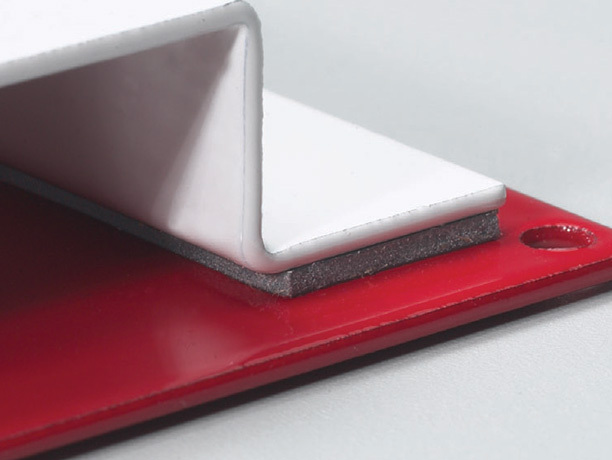

Custom Part Fabrication

Create highly custom flat elastomeric parts, double-sided tapes, thermal pads, and other components for wearable devices requiring compact, ergonomic designs.

- Build low-profile skin-adjacent parts, housings, and sensors with minimal bulk and maximum comfort

- SSimplify assembly and improve performance with optimized parts for skin-adjacent applications or inside electronics

Prototyping

Rapidly iterate wearable device designs with dieless cutting equipment and a vast in-stock catalog of stick-to-skin adhesives, films, pads, tapes, and more.

- Refine stick-to-skin wearables without tooling delays or high-volume commitments

- Iterate materials, layouts, adhesive performance, and more for comfort, durability, and performance before full production

Talk to a Converting Expert

Our team of experts is ready to chat and help whether you need advice finding the right material or are looking for custom converting capabilities. Get in touch today and move your project to the next step.