General Manufacturing & Assembly

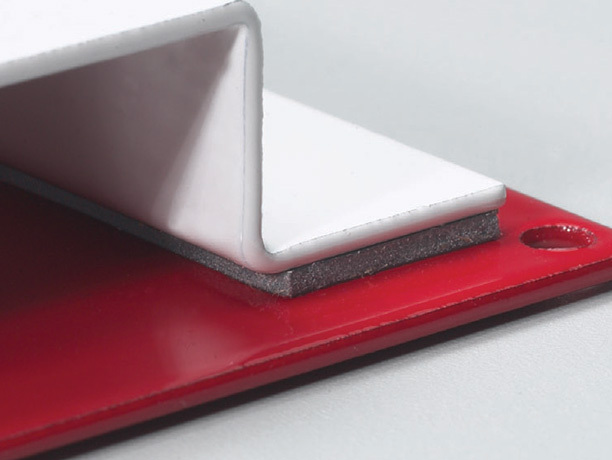

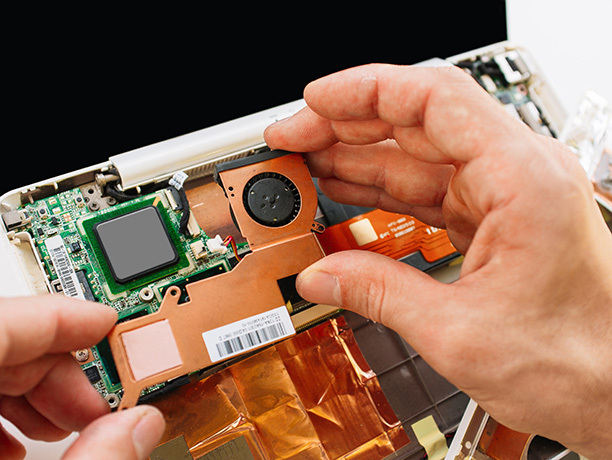

Improve manufacturing speed, product quality, and consistency across production environments with custom-cut and laminated tapes for bonding, masking, shielding, gasketing, vibration control, and beyond.

Applications

in General Manufacturing & Assembly

Custom Converting Services

Tape Slitting

Turn bulk tape logs into precise widths to match inventory requirements, build layouts, and production workflows.

- Reduce manual trimming and waste by matching tape rolls to parts, tasks, and automated application equipment

- Order foils, films, foams, and other specialty tapes in the exact width required for bonding, masking, and beyond

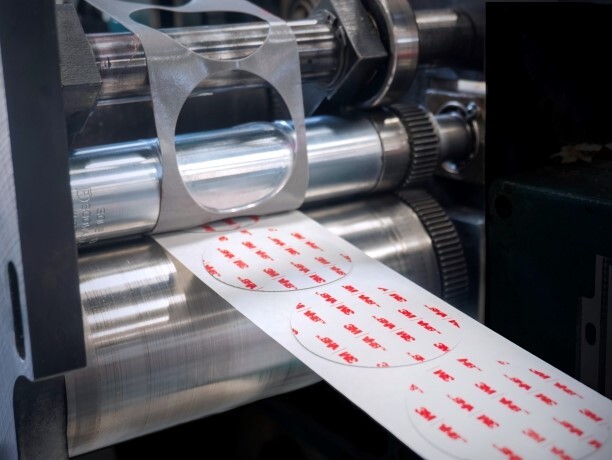

Die Cutting

Our precision, scalable die-cutting equipment creates clean custom parts from high-quality tapes at tight tolerances for various builds.

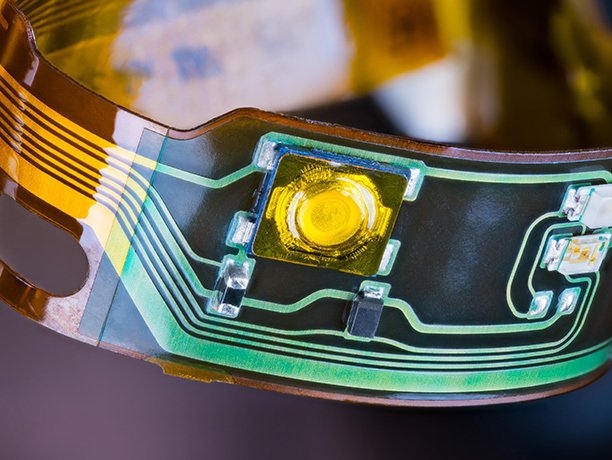

- Convert flat, flexible material into precision shapes for use in complex assemblies

- Eliminate manual cutting where custom sealing, masking, bonding, and specialty materials are used

Prototyping

Our prototyping services help design teams move quickly from concept to scaled production with tool-free iterations and low minimum order quantities.

- Iterate quickly with expert design support, easy CAD file integration, and a deep material catalog

- Quickly validate multi-layer laminations, die-cut gaskets, and other components

Custom Length Rolls

Break down jumbo logs and bulky rolls into shorter, more manageable tape roll lengths to simplify inventory, reduce overuse, and support distribution goals.

- Align tape lengths with automated equipment to reduce changeover, and hand out shorter rolls to reduce overuse in critical applications

- Tailor roll sizes to different bonding, masking, and sealing tasks across manufacturing environments

Talk to a Converting Expert

Our team of experts is ready to chat and help whether you need advice finding the right material or are looking for custom converting capabilities. Get in touch today and move your project to the next step.