Electronic Manufacturing

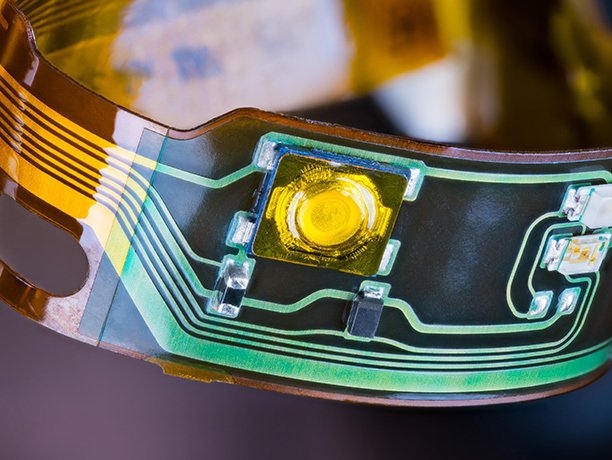

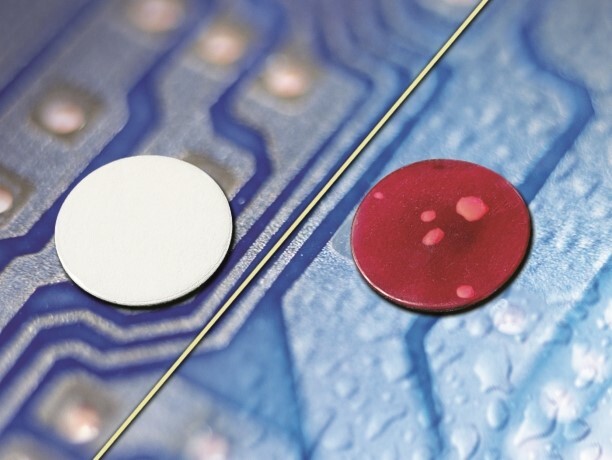

Increase efficiency in electronics and PCBs with custom shaped and stacked materials for masking, bonding, thermal management, gasketing, venting, shielding, and more.

Applications

in Electronic Manufacturing

Converting Services for Electronic Manufacturing

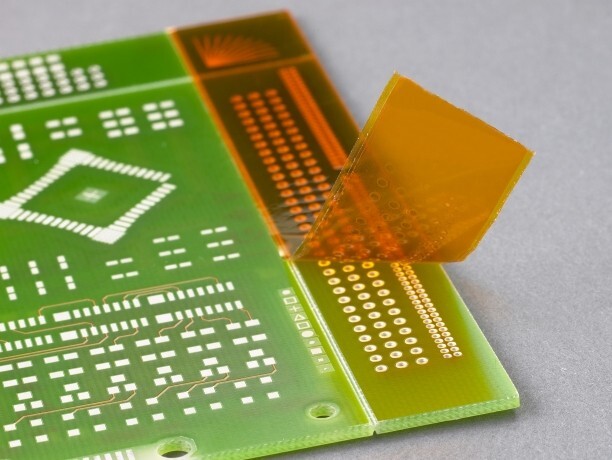

Die Cutting

Our precision rotary and flatbed die-cutting equipment creates clean, repeatable parts for tight tolerances in electronics.

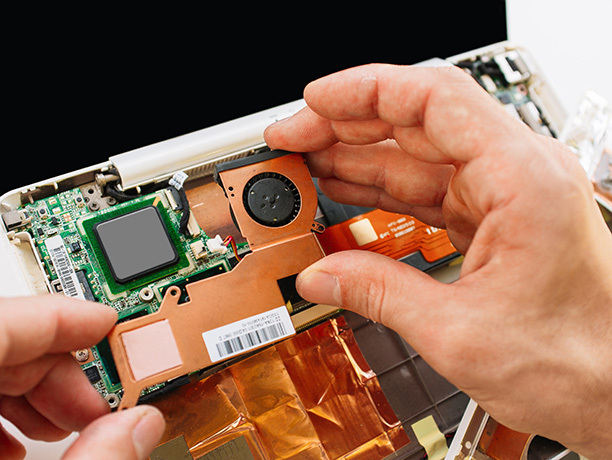

- Create consistent, ready-to-use parts to streamline PCB, battery and electronics assemblies

- Improve fit and function with custom shapes for isolating components, managing heat, or shielding sensitive areas

Custom Part Fabrication

We fabricate adhesive-backed parts, gaskets, tapes, and laminates to simplify complex assemblies and improve end-product performance.

- Turn advanced films, foils, and adhesives into purpose-built parts for electronics builds

- Evolve product lines confidently with the right materials and engineering support

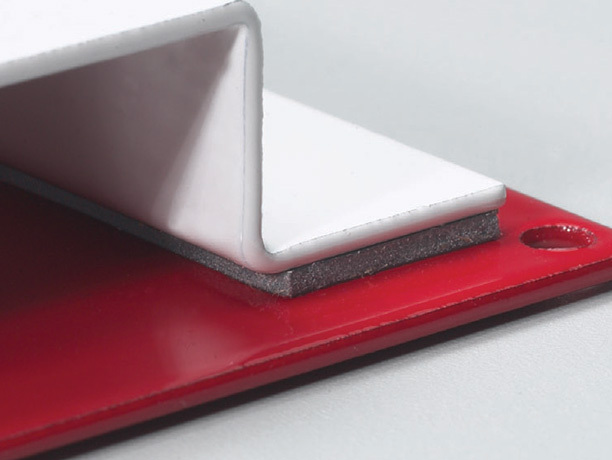

Multiple Lamination

Layer up to seven materials into one engineered construction for multi-functional, flexible parts in electronics.

- Combine foams, adhesives, films, foils, and more to for use in tight electronics

- Reduce part count by integrating thermal management, shielding, bonding, and more into a single laminated construction

Prototyping

Our rapid dieless prototyping process relies on our quick CAD workflows and converting experts to accelerate iterations and reduce tooling delays.

- Skip tooling costs and long lead times with samples from a wide library of in-stock prototyping materials

- Collaborate with our team to troubleshoot early, refine designs, and prepare for seamless production ramp-up

Talk to a Converting Expert

Our team of experts is ready to chat and help whether you need advice finding the right material or are looking for custom converting capabilities. Get in touch today and move your project to the next step.