Appliance Assembly & Service

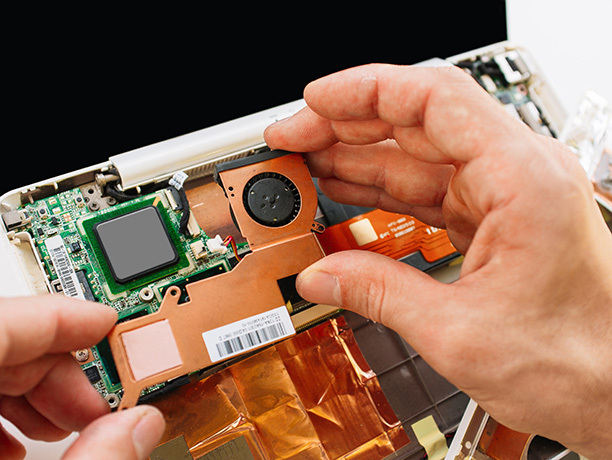

Improve the performance and durability of your appliance design while reducing input costs by customizing your tapes for optimal bonding, shielding, masking, gasketing, thermal management, and more.

Applications

in Appliance Manufacturing

Converting Services for Appliance Assembly

Die Cutting

Our precision die-cutting equipment creates complex, repeatable parts from all sorts of flat, flexible materials to solve tough issues in appliance designs.

- Shape high strength foam tapes to fit complex parts inside tight appliance housings

- Customize pads, foils, films, and papers to tackle unique jobs within appliance assemblies

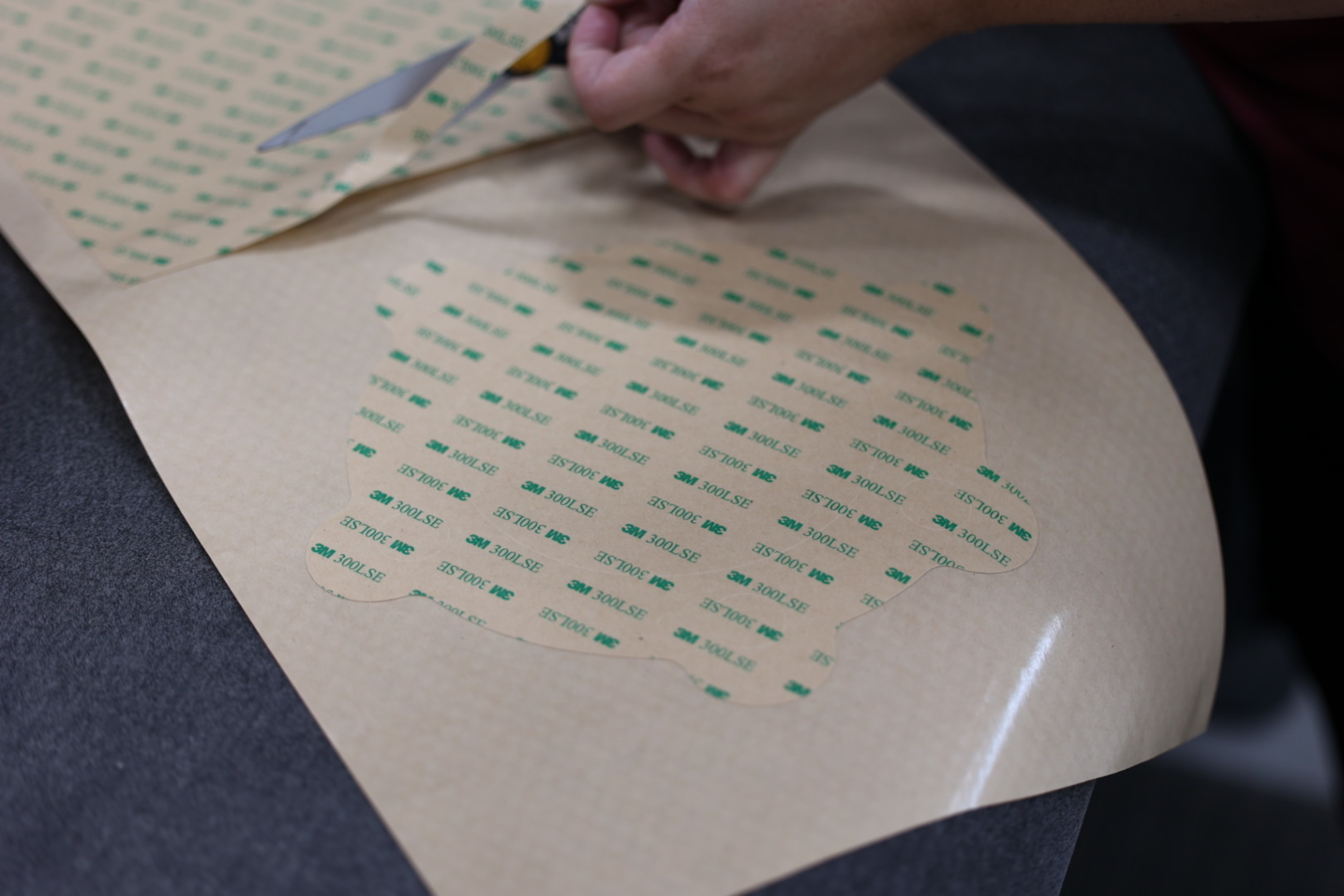

Extended Liners

Extended liners make tapes easier to use during appliance manufacturing, especially in tight areas and for repetitive tasks, by offering a simpler way to remove the backing.

- Improve ergonomics for workers, reduce scrapped parts due to messy liner removal, and speed up application for repetitive tasks

- Simplify field repair kits and workflows with easier-to-use tape designs

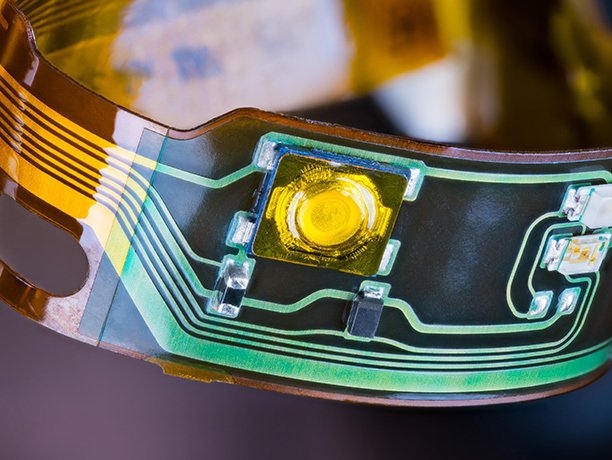

Multiple Lamination

Combine multiple materials into singular constructions to blend functions, reduce part counts, and simplify assembly processes.

- Build multi-functional parts for bonding, insulating, and shielding within compact appliance assemblies

- Streamline appliance production and reduce input costs by simplifying sourcing into a single prefabricated part

Tape Rewinding & Slitting

Customize tape length and width to conform with your inventory goals and appliance production plan.

- Reduce waste and improve fit with custom widths and lengths for bonding, masking, and thermal management

- Curate tape roll sizes to comply with automated assembly machines or specific manual tasks

Talk to a Converting Expert

Our team of experts is ready to chat and help whether you need advice finding the right material or are looking for custom converting capabilities. Get in touch today and move your project to the next step.