Engineer Your Tape Solution with a 3M Preferred Converter

As a 3M Preferred Converter, TapeCase helps engineers, OEMs, and operations teams transform advanced adhesive tapes and specialty materials into highly customized solutions.

As a 3M Preferred Converter, TapeCase helps engineers, OEMs, and operations teams transform advanced adhesive tapes and specialty materials into highly customized solutions.

As a 3M Preferred Converter, TapeCase helps engineers, OEMs, and operations teams transform advanced adhesive tapes and specialty materials into highly customized solutions.

Whether you’re prototyping a new component or looking to convert jumbo tape rolls into more usable formats, our deep knowledge of 3M technology and capabilities to convert 3M materials are ready to help you innovate.

TapeCase often works with teams who:

The experts at TapeCase work closely with 3M to help you spec in the right materials for your design, production requirements, and workflow. With ISO9001:2015 certification and support for cleanroom converting, TapeCase is a trusted converter partner for manufacturers worldwide.

Specify a finalized design or create a new one from scratch with our experienced converting experts.

Pair our material sampling library with our precision converting capabilities to optimize and validate a prototype.

Rely on our top-tier suppliers, strict quality controls, and hands-on help to ensure your product’s effectiveness throughout its lifecycle.

The 3M Preferred Converter designation recognizes select partners trusted for deep technical expertise, consistent quality, and proven problem-solving.

TapeCase earned the distinction through years of engineering collaboration, hands-on problem solving, and a commitment to helping customers get the most out of 3M materials. Our experts are trained on the 3M tape catalog, regularly prototype with their materials, specialize in converting their tapes, and help countless design teams shape how it’s used in real-world scenarios.

Our 3M converting expertise means:

For our customers, working with a trusted 3M supplier like TapeCase means faster access to 3M materials, better support during design and prototyping, and confidence that converted parts will meet rigorous performance and compliance standards.

We work with a wide range of 3M tape technologies and can convert them into nearly endless formats to support bonding, sealing, shielding, labeling, vibration dampening, and more. Our experts regularly convert:

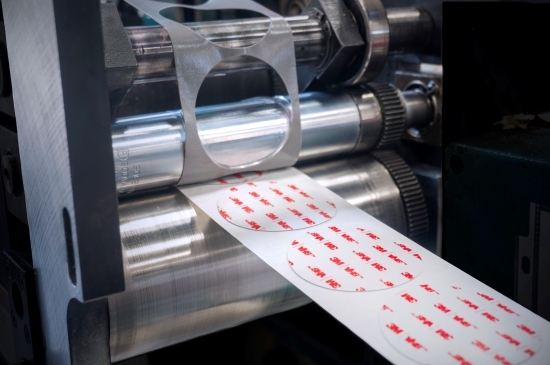

3M materials are used in everything from aerospace panels and automotive trim to medical wearables and industrial enclosures. By converting them into highly custom formats, TapeCase helps OEMs and other businesses reduce product assembly steps and improve end performance.

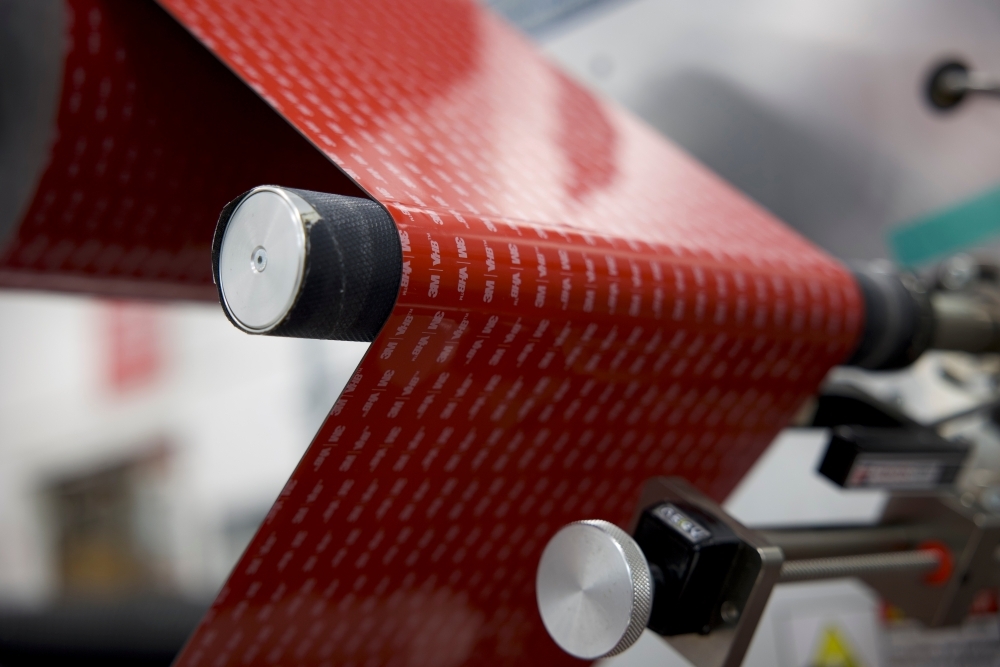

Our converting capabilities include precision slitting and rewinding, rotary and flatbed die-cutting, multiple lamination, jumbo roll processing, wide web lamination, and more — all tailored to the unique requirements of 3M materials.

Whether you already have bulk tape inventory or you’re starting from scratch, TapeCase will help you turn advanced 3M materials into custom solutions.

Located in the Chicago area, our converting operation combines precision equipment, engineering expertise, and a deep partnership with 3M to serve industries across North America.